Beyond Complexity

스마트 팩토리

Novas EZ의 스마트 팩토리에 대해 소개해드립니다.

Using the Internet of Things to establish Smart Processes

Assembly

- Smart product design with standards considering requirements of a smart factory

- Call-offs steered by machines according to available capacity

- Line and equipment balancing based on capacity, full flexibility on assembly sequences

- Connected equipment fot predictive maitenance activities, smart sensors for real-time data

- Trained operators with cross-functional skills

Outbound

- Fleet pooling for maximized utilization

- No outbound warehouse for finished goods, mixed customer deliveries, autonomous fleet steering

Sales

- Sales with insights into manufacturing storages and processec for real-time promotions based on availability at the plant

- High flexibility on production planning with lot size of 1, 1:1 synchronized with customer orders

- Auto Soldering

- Auto Testing Platfrom

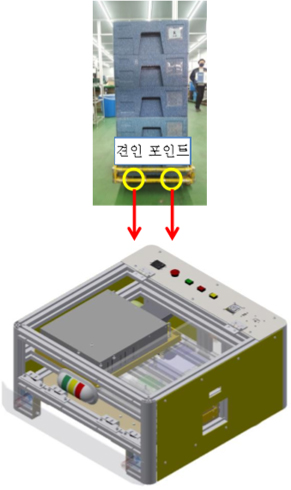

- AGV

PCB Ass'y의 주요 공정인 Soldering을

수납땜으로 운영됨에 따른 생산성

저하 및 열악한 작업환경을 Robot을 적용하여 개선함

수납땜으로 운영됨에 따른 생산성

저하 및 열악한 작업환경을 Robot을 적용하여 개선함

- Auto Soldering ROBOT 구축 내용

-

Desk Top Robot 방식

5축제어 X, Y1, Y2, Z, θ, 전용 제어

Soldrering Unit 및 고주파 전용팁 / 전용 Jig 설계 및 적용